High Grade Special Steel Forging

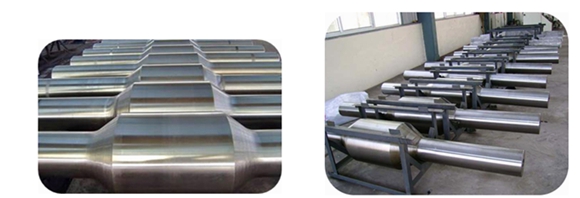

Integral Forging Stabilizer

According to API Spec.7 and SY/T5144, drill collar is made of AISI 4145 modified chromium- molybdenum alloy steel. All threads are

phosphated, copperized or cold rolled .

SCOTON can offer kinds of stabilizer, such as replaceable sleeve stabilizer, integral spiral blade stabilizer, WZ type integral blade

stabilizer, three roller stabilizer and non-magnetic stabilizer etc.

Mandrel bar

Our company is capable of producing a series of mandrel, such as MPM, PQF, FQM, with the diameter of Φ80-350mm, the length of

2500-17500mm, as a result of making the best use of our advantage in steel making, forging, heat treatment, machining plating

chromium adequately. The raw steel material is AISI H13 or 4CrMoSiV1, based on enterprise specifications.

Pipe Mould

Pipe mould, which was made from 21CrMo10 or 20-30CrMo, is the most important tool in the process of spheroidal cast iron pipe dies .

We provide many sizes of pipe mould the OD from DN80 to DN1200.

Main Shaft

Forgings for power station could meet JB/T standard or be produced according to the order. The main process is EBT +LF/VD(ESR)

melting + cogging down by hydraulic press + forming by rotary forging machines. The main products includes rotor for 25-200MW

steam turbine, rotary table and impeller for 25-200MW steam turbine, rotary forgings for 20-200MW steam tubine, large forgings for

hydrao turbine and turbine generator, shafts or axles for wlwctric motor, rotor and shaft for less than 25MW turbine. the delivery condition

could be machining or quenching and tempering.

High Pressure Boiler Steel Tube

we can offer kinds of high pressure tube.

Here are some materials and specification:

SA106C 12Cr1MoVG P12 P22 P91 P92

NON-MAGNETIC STEEL

CERTIFICATE FOR NON-MAGNETIC

STABILIZER FORGING AND DRILL COLLAR

Chamical Composition (%)

|

Chemical Element |

C |

Si |

Mn |

P |

S |

Cr |

Mo |

N |

Ni |

Nb |

|

Smelt Composition |

≤0.03 |

<1.0 |

19~22 |

≤0.03 |

≤0.015 |

13.8~15.5 |

0.50~0.07 |

0.30~0.50 |

1.00~1.50 |

≤0.01 |

Mechanical Properties

|

Item |

Required |

Our products |

|

σ0.2 (Mpa)Yield Strength |

≥689 |

≥810 |

|

σb (Mpa) Tensile Strength |

≥823 |

≥920 |

|

δ4 (%) Elongation |

≥25 |

≥35 |

|

Z (%) R.A |

≥50 |

≥65 |

|

Akv (J) Impact Text |

≥85 |

≥150 |

|

(HB) Brinell Hardness |

285~341 |

310~341 |

|

(HB) 1” Of Subcutaneous Hardness |

285~341 |

300~330 |

|

U.S. Inspection |

SY/T5144-2007 |

|

The Magnetic Field Gradient |

△B ≤0.05μT |

|

Relative Magnetic Permeability |

μr ≤1.010 |

μr ≤1.005 |

|

The Intergranular Corrosion Test GB/T4334.5-2000 |

|

Grain |

4-8 |

5-8 |

Range of size

3-1/8”~12” Non-magnetic drill collar

6-1/2”~36” Non-magnetic Stabilizer

If the buyer have special requirements of the chemical composition

and mechanical properties, our company can try to meet it by adjusting

the producing process.